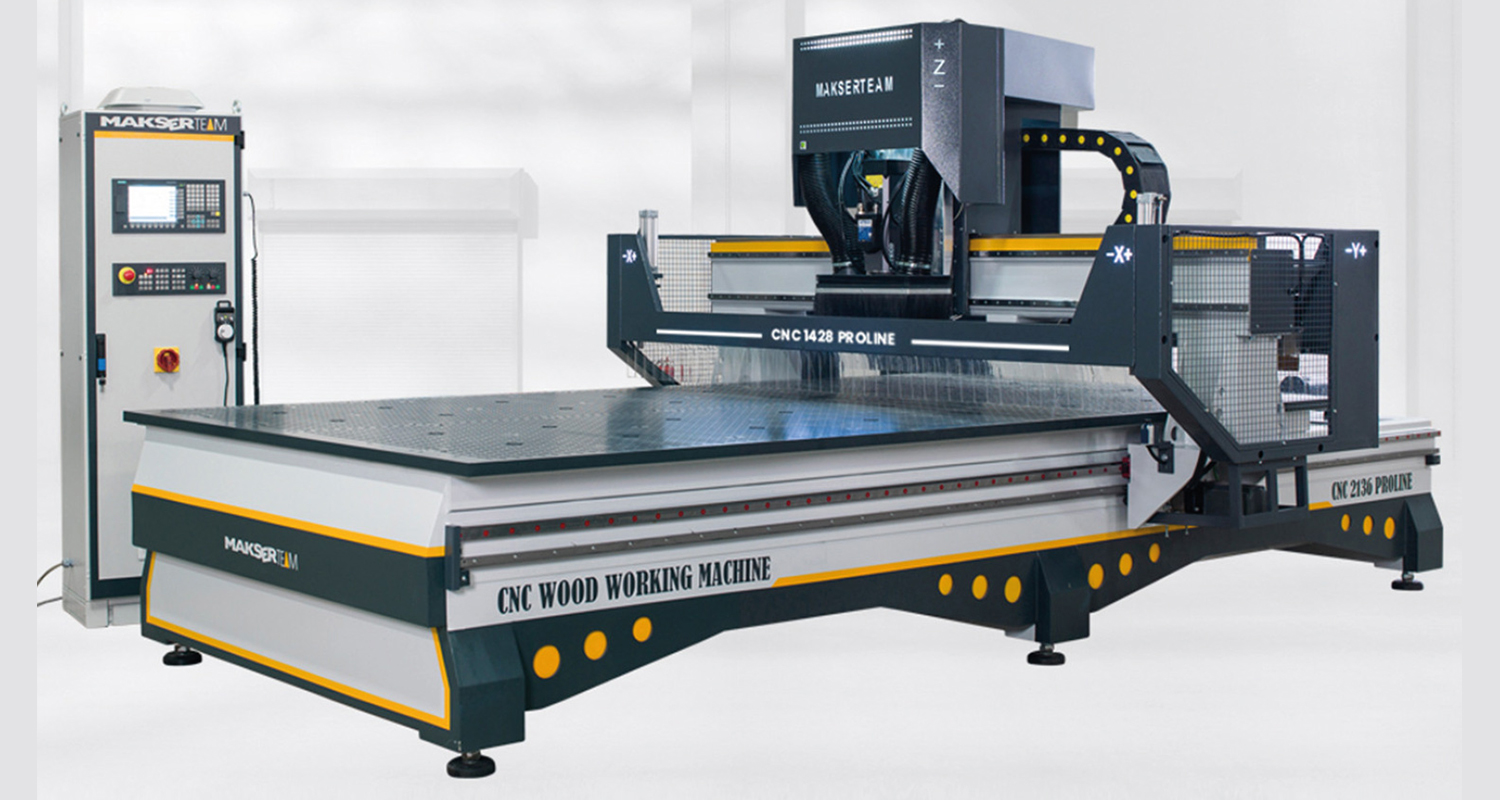

CNC Router Proline

- Home Page

- Products

|

PRODUCTS |

PRODUCTS SPECIFICATION |

BRAND / MODEL |

|

CONTROL UNIT |

SINUMERIK 808D / M300 A |

SIEMENS / DELTA |

|

X AXIS MOTOR |

1.5 KW 2000 D.D. |

SIEMENS / DELTA |

|

Y AXIS MOTOR |

1.5 KW 2000 D.D. |

SIEMENS / DELTA |

|

Z AXIS MOTOR |

1 KW 2000 D.D. BREAKED |

SIEMENS / DELTA |

|

ELECTRIC SPINDLE |

8,5 KW 24.000 RPM |

HITECO |

|

VACUUM PUMP |

13 KW GP 600 E |

POMWAK/DVP/GEV |

|

VACUUM WORKING TABLE SIZE |

1 1/4’’ – 5 AREA 32 CENTER |

TORK |

|

VACUUM TABLE SIZE |

18mm X 2 COMPACT |

ASD/GENTAŞ |

|

REDUCER |

FA 100 1/10 BODY |

FRAMO MORAT |

|

PACK MOTION GROUP |

25X25 MOD2 HELICAL |

FRAMO MORAT |

|

PINION MOTION GROUP |

Z32 MOD HELICAL |

FRAMO MORAT |

|

LINEAR MOTION GROUP X AXIS |

EXTENSIVE TYPE G3 25 |

STAFF |

|

LINEAR MOTION GROUP Z AXIS |

EXTENSIVE TYPE G3 25 |

STAFF |

|

LINEAR MOTION GROUP Y AXIS |

EXTENSIVE TYPE G3 35 |

STAFF |

|

BALLSCREW |

25 X 475 |

GTEN |

|

AUTOMATIC LUBRICATION SYSTEM |

2 LT / HYDRO OIL HD 46 |

SCHNITZER |

|

TOOL HOLDER ADAPTOR |

HSK F-63 ER32 |

IMS |

|

TOOL RESET |

SWITCH SYSTEM |

TELEMECANIQUE |

|

MITER SYSTEM |

3 + 4 7 PISTONS |

EXPFLEX |

|

DUST SUCTION |

OTOMATIC DUMMY FLANGE |

FTC |

|

TOOL CHANGING |

UNDER THE BRIGE 10 PCS |

MAKSER |

|

TOOL CHANGING APPARATUS |

PLASTIC BREAKABLE FORK END |

MAKSER |

|

CLADDING |

PROTECED PROLINE |

MAKSER |

Compact Table and Vacuuming System

The work table is made of 18mm double layer compact material. Thanks to the 5 zones 32 central vacuuming system, each zone can be operated independently. Thus, all parts, including small ones, can be vacuumed.

High Quality Ground and Hardened Rack, Rail and Gear System

By using high quality ground and hardened rail, rack and gear systems, axis movements are aimed to give the best results at the highest speed.

Axis Control with Servo Motor

All axes in the machine can be controlled by servo motor. With servo motor: millimeter measurement produces excellent results with high acceleration and high precision.

Referencing with Stop Pistons

With the automatically controllable stop pistons on the machine table, part referencing can be done easily.

Control unit

New generation Siemens and Delta industrial CNC control unit and easy-to-use interface program.

Creative Solutions with Flexible CAD/CAM Applications

With the help of Alphacam, Pegasus and Cabinet programs, it provides convenience for powerful designs and production.

Single Machining Center for Different Types of Applications

8.5 KW HSK F63 spindle motor for sizing, surface treatment, modeling etc. It allows you to get better results at higher speeds in milling applications. Processing engine wood, aluminum, plastic, aliquot, plexiglass, etc. can process materials.

Automatic Tool Change

With the Automatic Tool Changing System, the machine can perform fast tool changing operations wherever it is.

Automatic Tool Length Measurement

The precision tool measuring probe automatically measures the tool lengths and records them on the screen on the control unit. The Automatic Tool Length Gauge probe helps reduce tool setup time and minimizes the possibility of mistakes.

Automatic Lubrication System

With the Automatic Lubrication System, all moving systems are lubricated automatically at certain time intervals. Manual lubrication button on the Lubrication Tank can be used at any time.

Designed to automatically unload the plates from the table after processing, this system aims to maximize production performance by eliminating time loss and human labor.

High quality grinded and hardened rail, rack and gear systems are used to obtain the best results in axis movements at high speeds.

All axes on the machine are controlled by servo motors. With the use of servo motor; It gives excellent results with millimeter measurement, high acceleration and high precision.